High Speed Sensor

Blink HS is specifically designed to measure ultrafast lasers with rep. rate in the range 1kHz – 1MHz and pulse durations down to fs. It is based on a novel technology (patented) that allows to combine the fast response of a photodiode and the broadband and high power operation of a thermopile. Blink HS series is available with Air and Water cooling.

BM-W-20W-14-T

14mm x 14mm, 1mJ – 10mJ

| KEY FEATURES |

|

COOLING: Water DESIGNED FOR ULTRAFAST LASERS: |

|

BROADBAND OPERATION: 250nm-1100nm; 10600nm |

| MAX. AVERAGE POWER: 20W |

| ENERGY MODE: Measure Energy of each pulse with rep. rate up to 1MHz |

BM-A-15W-14-T

14mm x 14mm, 1mJ – 10mJ

| KEY FEATURES |

|

COOLING: Forced Air DESIGNED FOR ULTRAFAST LASERS: |

|

BROADBAND OPERATION: 250nm-1100nm; 10600nm |

| MAX. AVERAGE POWER: 15W |

| ENERGY MODE: Measure Energy of each pulse with rep. rate up to 1MHz |

HSM-1000 High Speed Meter

|

CONNECTIVITY TO PC: Ethernet |

| TRIGGERS: Triggers IN and Trigger OUT |

| SOFTWARE: Dedicated GUI |

HS Sensor Head for High End Pulsed Lasers

The Pulsed Mode Laser performances are rapidly progressing under the pressure of the requests form the electronic, display, automotive, medical, photovoltaic (just to mention the most relevant) markets, and are nowadays the key enabling technologies to those markets.

The new high end sources are restless and quickly migrating from Academic Laboratories to Industry, and producers are pushing the laser performances to higher repetition rate (several MHz), shorter pulse duration (femtosecond and picosecond), high energy/pulse (up to milli Joules), higher average power (up to several hundred Watts), wide wavelength range (e.g. nanosecond pulsed CO2).

How to perform metrological monitor of such very powerful high end devices in such a wide variety of parameters?

How to support the implementation of the Industry 4.0 global trend by the Laser Industry?

The answer is the NEW Blink HS High Speed Sensors (International Patented), a new line of metrological sensors based on innovative concepts that perform at least 5 (five) times better than the current state of the art competitor, as far as the paramount laser repetition rate parameter is concerned.

The NEW Blink HS High Speed Sensors comes along with HSM Meter and advanced HS GUI, perfectly suited for Laboratory use (Academic, Industrial R&D) as well as OEM applications (Laser Source manufacturers, Laser System Integrators).

BLINK HS – SPECIFICATIONS |

High Speed Meter (HSM) – Hardware

LaserPoint developed a specifically designed High Speed Meter (HSM) for HS sensor which is able to provide a very fast processing speed of all acquired data coming from the HS sensor.

LaserPoint’s new measurement system for pulsed lasers with very high pulse-rate extends the possibility of characterizing individual laser pulses for all pulsed sources up to 1000KHz repetition rate.

HSM electronics is based on state-of-the-art chips with System On Chip (SoC) design, integrating in a single chip a multicore microprocessor system, a DSP (Digital Signal Processing) computing unit and a data acquisition system at high speed and high resolution.

The Hardware subsystem allows to compute various parameters of the laser beam under test (peak, frequency, energy, power), averaged over a short time sampling period, but also to detail down to the single pulse values or pulse train as well as providing the most common statistics (means and variances) on the acquired data and in real time. All calculations are performed in real time without interruption or calculation limitation, thanks to the integrated DSP motor which does not lose any impulse and guarantees absolute measurement reliability.

The DSP is completely reprogrammable unit which can allow, in the future, to add new features and system evolutions without changing the hardware itself, but with the simple download of a new board firmware.

Not less important, the electronics allow you to keep up and acquire signals from the sensor at a very high sampling rate and a resolution of 16bit, while the analog input is made with RF (Radio-Frequency) high end amplifiers with very low noise and very high linearity .

Last but not least, Trigger-IN and OUT connections and the communication port with the PC are part of the hardware equipment system. The PC port is the latest generation Ethernet, operating at 100 Mbit but also at GigaBit Ethernet able to support the maximum data acquisition speed and transfer to the management SW operating on a Windows 10 PC.

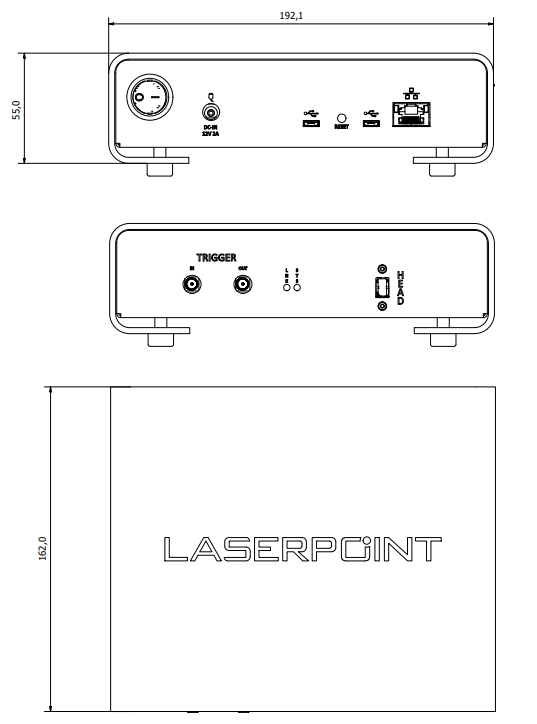

HSM – DRAWING |

HSM – Graphic User Interface

The Graphic User Interface (GUI) complements the new Laser Point Energy Meter HSM and is dedicated to the HSM module and Blink-HS sensors.

Equipped with the latest generation graphics engine, the software is fully compatible with Windows 10 64bit multicore PCs of which it exploits all its potential.

The GUI implements the graphic management via GPU, by which it is possible to perform Zoom, Pan, exactly as you are used to do on each modern device in a fluid and precise way, to the benefit of the user experience.

The GUI comes with multithreading architecture that allows to process and display incoming data from the HSM module directly in real time, while all graphic functions remain active. The result is to make the analysis and measurement of the high repetition rate laser parameters, but not only, a new experience to discover the behavior of modern lasers that has not been possible so far with such simplicity and immediacy.

Obviously the most common and practical functions are integrated in the GUI, such as: the display of waveforms of the acquired signal, that thanks to HSM pushes to a resolution of 2ns; waveform comparison, as in modern oscilloscopes; import / export in various formats and modes (CSV, PNG, etc.); in addition to the classic colour setup and graphic of every GUI option.

Finally, the GUI does not forget as well to be the means of management and maintenance of the HSM module, to which it offers full control of the Hardware parameters such as the polarities of the triggers, threshold levels, setup of the oscilloscope mode, etc. as well as the Firmware update and diagnostics (alarms, status).