Sensors based on the standard longitudinal thermoelectric effect are commonly designed adopting multiple electrically interconnected thermocouples, which can measure a heat flux axially across a suitable substrate. This type of sensors using the standard thermoelectric effect are an evolution of the common radial thermopile design. Working on a thermal principle, the spectral acceptance region of this kind of sensors is still broadband. However, the thermal design of this kind of sensors only allows for relatively slow response times (currently greater than 100 ms). Moreover, the design of multiple axial thermocouples often implies a scarce coverage of the active area of the sensor.

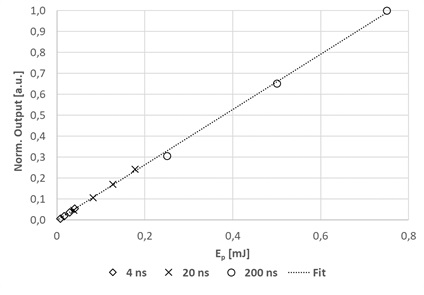

Sensors using the Laser Induced Transverse Voltage (LITV) effect also transduce a thermal gradient into an electric signal. Thin films of deposited suitable materials can show a transverse thermoelectric response to laser-irradiation. That is, if a thermal gradient is present along the normal direction to the film surface, a thermoelectric response is generated, longitudinally to the plane of the film surface. The adoption of the LITV effect has the intrinsic advantage of showing a good conversion efficiency of a thermal signal into an electric voltage, while showing response times in the nanosecond timescale. Another advantage of the LITV based devices over standard thermoelectric devices is the uniform coverage of the active area, with respect to a design based on axially disposed thermocouples.

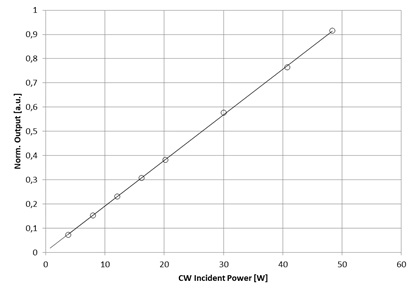

The advantage of sensors using the LITV effect over pyroelectric sensors and photodiodes for laser radiation measurement is the combination of an overall fast response time, broadband spectral acceptance, high saturation threshold to direct laser irradiation and the possibility to measure pulsed as well as cw-laser sources.